Edward Hospital & Health Services is a full-service, regional healthcare provider offering sophisticated medical specialties, located in west suburban Chicago.

Edward Hospital & Health Services is a full-service, regional healthcare provider offering sophisticated medical specialties. It is located in the western suburbs of Chicago, with two main campuses in Naperville and Plainfield, plus outpatient facilities and physician offices throughout the region.

Working With a Five-Year Plan

Edward Hospital has developed a five-year capital plan for replacements or upgrades to its X-ray systems. This approach to establishing spending priorities includes a yearly assessment to adjust for technology advances and changing needs. During the annual budgeting process, managers, technologists and others in the department conduct an evaluation that includes four focus areas:

1. Equipment audit: We maintain an inventory of capital equipment for each site within our hospital network and assess the technical health of imaging systems each year. We typically plan for a seven-year lifespan, but continuously evaluate the system’s age, condition, service history and performance against specifications.

2. Utilization analysis: Once the performance of each imaging system has been assessed, we review crucial data on how each is being used. Multiple sources are consulted, including Carestream’s reporting tools; a Bayer platform for dose monitoring, protocol efficiencies and equipment utilization; as well as manual data calculation, benchmarks from KLAS and our advisory board. Using these tools, we establish utilization-rate benchmarks and track total volume, procedure and exam times, as well as downtime and available capacity.

3. Market opportunity forecasts: Each year we explore our local market to identify changes in demographics and referral sources. Variances can place new demands on the imaging fleet. These factors support smart capital planning to ensure we have the right equipment to maintain current levels of performance and prepare for future volume and revenue goals.

4. Delivery of patient care: Imaging equipment is evaluated in terms of how well it supports the health of the hospital and its patients. Leaders of various clinical areas are consulted and drivers of physician productivity and positive patient outcomes are discussed.

The Result

This comprehensive review allows us to make better-informed investments. It also gives us a disciplined approach for using existing assets to achieve a greater return on our investment. Taking a five-year capital view provides a model for prioritizing the investments we need to make in the future.

Converting from CR to DR

Our hospital’s conversion to digital X-ray exemplifies the efficacy of this evaluation framework. In 2004, we augmented an investment in PACS by installing CR systems to provide digital image capture. Over time we tracked the performance of these systems and identified the need to make investments in full digital radiography. The decision was further defined by these key factors:

• Physicians in the OR, ICU and ED needed expedited access to high-quality images;

• Staff workflow was inefficient and negatively impacted operational productivity and patient throughput;

• National initiatives for dose reduction resulted in new hospital benchmarks; and

• A new outpatient facility had demanding targets for short patient wait times and a streamlined imaging volume.

Our schedule for the CR to DR transition began in 2012 and spread the cost out over three years. To extend the life of existing X-ray rooms and portable units, we began by retrofitting eight rooms and three portables with DR detectors. We prioritized the ED, OR and ICU — our critical care environments — as primary targets for improved quality of bedside imaging and accelerated patient-care decisions.

The Next Phase of Our Conversion

The following step was the planned installation of several fully- and semi-automated DR rooms to deliver expanded image-enhancement features, greater positioning flexibility, and higher image quality in our ER, inpatient and outpatient areas. We also budgeted for a fully automated DR room in our new outpatient center in South Plainfield, Ill. This now expedites all types of X-ray exams, which helps reduce patient wait times and allows the clinic to handle more patients. In addition, our existing CR systems were leveraged by reallocation to our lowest-volume off-site locations, where they now conduct about 200 exams a month.

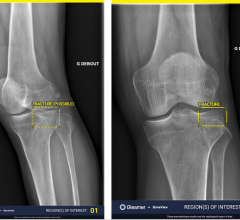

Addressing the Issue of Dose

Our desire to deliver the highest level of patient care led us to conduct a dose analysis for both CR and DR imaging systems. In testing conducted with our physicist, we confirmed that new and retrofitted DR systems could deliver a dose reduction of up to 60 percent when compared to CR systems. This analysis was a primary reason our strategic plan for capital investment in DR systems was approved by hospital administrators.

Today, we are considering replacement of some retrofitted systems with new systems in areas where current equipment is not functioning up to full performance standards. Where possible, we intend to keep our detectors and leverage our investment by using them in our new DR systems — this is also projected to reduce costs.

Words of Advice

Should you consider adopting the approach as outlined here, it’s important to note that your work is not complete when strategic capital investments are in place. Ongoing management of imaging assets is required for keeping equipment functioning at the highest levels, for capturing the projected return on investment and achieving all desired clinical advantages. If your experience is like ours, two of the most important issues to manage will be:

1. Getting staff to view the detectors as strategic investments and handle them with great care.

2. Addressing the persistent issue of “dose creep.”

Regarding this second issue, software that monitors exposure data by system and user is an invaluable tool for keeping dose at appropriate levels over time. This tool will allow you to identify technologists who are using excessive exposure ranges for various exams — so you can then educate them on the proper approach.

In addition, such management tools typically allow fast and easy tracking of other issues as well — such as retakes, overall technologist productivity and more. I highly recommend including these systems in your capital plan to enable monitoring that helps ensure both staff and equipment are performing at desired levels.

Case study supplied by Carestream Health.

February 10, 2026

February 10, 2026