May 5, 2011 – GE scientists are already studying additive manufacturing techniques to reduce labor and costs on ultrasound devices. Here, the key aspect is the transducer, which is expensive to produce using current manufacturing techniques.

Michelangelo once described his technique as follows: “I saw the angel in the marble, and carved until I set him free.” For decades, the same idea has fueled the manufacturing of tiny, delicate instruments: you take a block of material and cut microscopic grooves in each piece, shaving away the excess one by one until it’s complete. The process works, but it takes time and money, making the equipment incredibly expensive to produce.

Recently, scientists around the world have been experimenting with a new technique known as “additive manufacturing.” Rather than taking a block of metal and shaving or cutting into it, researchers are growing the device from the ground up, a process also known as 3-D printing.

This week, GE Global Research announced it has created a new lab at its upstate New York headquarters dedicated entirely to additive manufacturing. Since GE produces a number of small, sophisticated devices, the lab’s research may cut down on an expensive, time-consuming process.

The process uses software to feed an instrument template into a 3-D printer, layering thin filaments of metal atop one another into the template’s pattern. Since no wasted shavings are produced, the process substantially lowers the cost of raw material. Plus, manufacturers no longer have to build an expensive physical template to create the microcuts – instead, they just write the software code, and the printer does the rest.

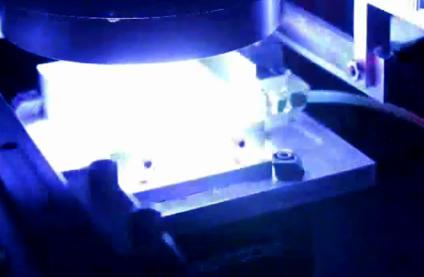

GE scientists are already studying additive manufacturing techniques to cut costs on ultrasound transducers. As building ultrasound equipment has grown less expensive and faster, costs of producing the tiny metal transducer has stayed stubbornly high – each transducer has tiny intricate patterns across it. Applying new additive techniques, which can print these intricate patterns on the probe all at once, can save hours of cutting and refinement.

To create the transducer components, a thin layer of ceramic slurry is spread on a plate, the system templates the form to be created and an ultraviolet light is used to fix the form in the slurry.

“For as long as the world has been making things, manufacturing has been a game of subtraction where you cut and machine parts down into the product you want,” said Prabhjot Singh, a mechanical engineer and project leader on the ultrasound project. “With new additive manufacturing processes, the traditional ways of manufacturing are being turned upside down.”

For more information: www.gereports.com/smart-industry-the-additive-manufacturing-revolution/

February 05, 2026

February 05, 2026