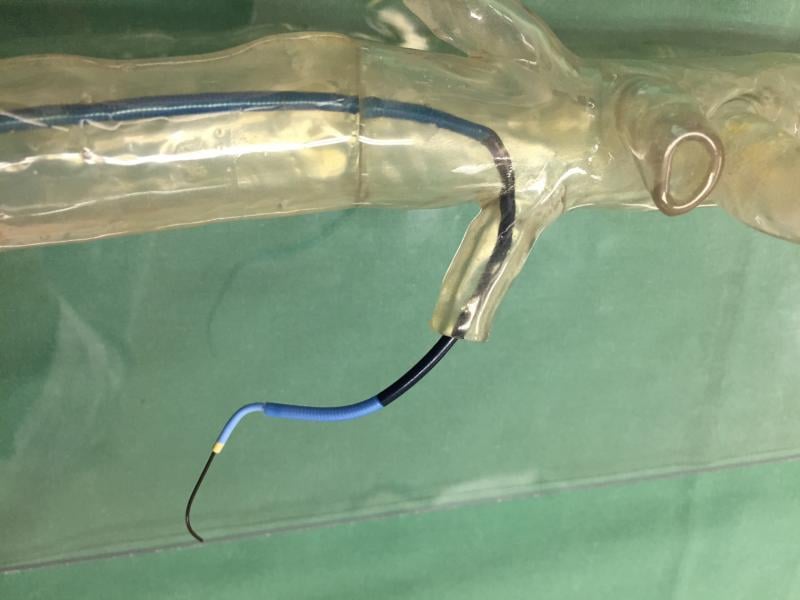

Transparent Stratasys 3-D-printed model of a patient-specific aortic arch, used by the University Hospital Mainz to practice complex endovascular surgeries. Photo courtesy of Business Wire.

November 16, 2017 — Stratasys Ltd. announced that surgeons at the University of Mainz Cardiothoracic and Vascular Surgery Department in Germany are using Stratasys PolyJet 3-D printing to transform the hospital’s surgical planning process for complex, life-critical vascular cases. According to the University hospital, the use of 3-D printed models for surgical planning has seen a significant reduction in costs at the institution when designing and fitting implants — while the hospital reports relevant time-savings during surgery, leading to an improvement in patient outcomes.

As an internationally recognized Center of Excellence when it comes to its Cardiothoracic and Vascular Surgery, the University Hospital Mainz provides research and patient care in areas related to the heart, thorax and blood vessels in the human body. The hospital treats several patients suffering from life-threatening aortic illnesses needing immediate attention and complex, patient-specific surgical treatment. According to Prof. Dr. Bernhard Dorweiler, head of the Department of Vascular Surgery at University Hospital Mainz, the adoption of 3-D printing is playing a crucial role in elevating the standard of patient care.

“On average, CT [computed tomography] scans with 1,000-2,000 images can be made per vascular-related patient case, which the surgeons use to analyze and diagnose the illness. This can be ambiguous and time-consuming when the issue is complex,” said Dorweiler. “With 3-D-printed models, we can quickly understand the individual patient anatomy and best determine the type of treatment required to successfully treat it.”

This was exemplified in a recent case whereby Dorweiler and his team were approached by a 53-year-old woman who had already been turned down by several other hospitals in Germany and beyond – such was the complexity around the illness and the potential risk of operation. Due to an aortic malformation close to the heart, the patient was suffering from a bulging blood vessel on her neck. Recognizing the need for urgent medical attention, Dorweiler and his team reviewed CT scans, however the results did not provide the level of clarity required to make an accurate diagnosis.

“Looking through the CT scans, it was impossible to clearly visualize the anatomy,” said Dorweiler. “So we decided to 3-D-print a model, and it was then for the first time that it became clear what the origin and magnitude of the problem was. Not only did we use the model to explain our findings to the patient to increase her compliance for the planned three-step operation, but we even took it into each of the three surgeries as a point of reference during operation, which was crucial to the successful outcome.”

To date, treatment of complex aortic illnesses with the endovascular method has been a difficult procedure, with surgeons relying on a monitor to implant a small stent through the arteries to be placed at the affected area of the aorta. In a recent case, Dorweiler and his team faced this challenge with a very complex case of aortic arch aneurysm. Requiring an intricate implant, the team undertook a pre-operative simulation of the surgery using a stent prototype and 3-D-printed aortic arch model of the patient. This process has since been repeated across several cases with surgeons able to practice surgery on the model repeatedly, ensuring the correct design and fit of the stent implant the first time — significantly reducing time and cost in the operating theatre.

“As pointed out in current published studies, there are savings in operating time of 5-45 minutes when using 3-D-printed models prior to surgery,” said Dorweiler. “Research is still ongoing, but if you take an average surgery time of 2-4 hours, you are looking at time savings of up to 40 percent. When you are dealing with complex vascular cases every day, these time-savings can be the difference between life and death.”

At the forefront of German medical research and development, the Vascular Surgery Department at the University Hospital Mainz has an extensive training facility, in which 3-D printing is integral.

“We use the Stratasys Eden260VS 3D Printer in our BiomaTicS research platform to produce models of aortic anatomies from real-life cases, so that we can use them to teach future vascular surgeons how to successfully perform complex endovascular surgeries,” said Dorweiler. “With the ability to 3-D-print patient-specific aortic models in clear transparent material, the trainees can practice endovascular procedures and learn difficult Wire-Skills using the accurate replicas of blood vessels. For healthcare, it is crucial that we continue to leverage the capabilities of 3-D printing for medical training, education and research for future breakthrough-implementation.”

For more information: www.stratasys.com

April 18, 2025

April 18, 2025