January 23, 2018 – At the 2017 annual meeting of the Radiological Society of North America, Nov. 26-Dec. 1 in Chicago, 3D Systems announced a new D2P (DICOM to PRINT) technology that helps clinicians and radiologists quickly create accurate, digital 3-D anatomical models from medical imaging data.

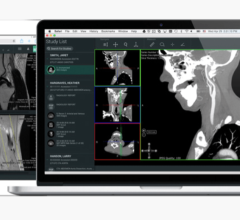

The company also announced its new Volume Virtual Reality (VR) technology that allows physicians to upload patient scan data to D2P and immediately visualize medical datasets in virtual reality without time-consuming pre-processing or segmentation. It produces results similar to those shown on high-end imaging workstations, but is rendered in virtual reality compared to standard flat screens.

Visualization in virtual reality greatly enhances 3-D understanding of structure and scale and can be used as part of routine examinations, or preoperative planning of surgical procedures. This new technology is available now as part of an integrated application through 3D Systems’ D2P offering.

Also announced at RSNA, 3D Systems signed an agreement with Philips to accelerate medical progress in improved planning and patient outcomes. Philips customers now have seamless access to expedite 3-D printing to create physical 3-D models to help physicians understand patient anatomy that is difficult to visualize, and deliver personalized medicine in complex cases.

At RSNA, 3D Systems showcased examples of patient-specific models in three materials, each printed using a different technology, including SLA (Stereolithography) using a biocompatible resin with the ability to highlight vital structures. These models can be sterilized for reference in the operating room.

“In just over a decade, 3-D printing has made patient-specific anatomical models routine. From pre-surgical planning to using the models as guides in the operating room, these tools have made complex procedures more simple and precise,” said Evan Garfein, M.D., chief, Division of Plastic and Reconstructive Surgery, Montefiore Health System. “With the arrival of D2P software we now have advanced software and 3-D printers that are accessible to surgeons at the point of care. It is the beginning of a new era in personalized medicine and surgical 3-D printing.”

For more information: www.3dsystems.com

April 18, 2025

April 18, 2025