December 11, 2018 — GE Healthcare and VA Puget Sound Health Care System, Washington, recently announced a partnership to accelerate the use of medical 3-D printing in healthcare. As part of their research agreement, GE Healthcare will provide software and workstations, and the VA will provide input on its use of the technology. Prior to this agreement, the VA has used 3-D software that is not designed for medical use. Now, the VA will use GE software designed specifically for the medical field – which is expected to reduce the time it takes to create 3-D models from hours to minutes.

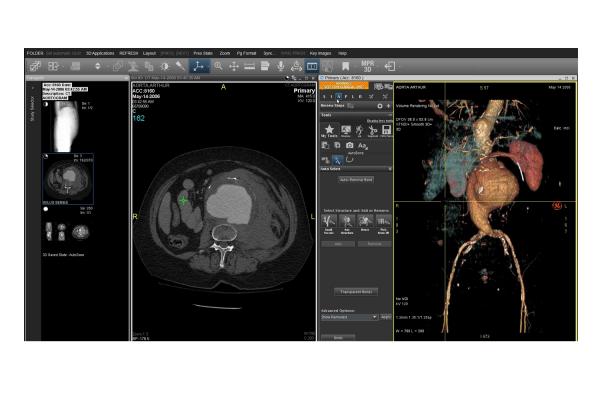

VA Puget Sound provides comprehensive care to more than 110,000 veterans across its nine facilities in the Pacific Northwest. Building on its 3D printing network, VA Puget Sound and the Veterans Health Administration Innovators Network will integrate GE Healthcare’s advanced visualization AW VolumeShare workstations with 3-D printing software across its facilities in Seattle, San Francisco, Minneapolis, Cleveland and Salt Lake City. VA radiologists specializing in cardiology, oncology, orthopedics and other areas will use this technology and software to develop new 3-D imaging approaches and techniques to deliver improved precision healthcare for U.S. veterans.

“The Veterans Health Administration has been on the forefront of bringing 3-D printing to the bedside, and we are thrilled to join forces with GE Healthcare to enhance and accelerate its adoption,” said Beth Ripley, M.D., Ph.D., VA Puget Sound radiologist, VA innovation specialist and VHA 3D Printing Advisory Committee chair. “For most radiologists, 3-D images are limited to reconstructions on a computer screen. By harnessing the power of 3-D printing with a rich data set, we are able to pull images out of the screen and into our hands, allowing us to interact with the data in a deeper way to fuel innovative, personalized care based on the unique needs of each of our patients.”

The use of 3-D medical printing in healthcare is still very much in its infancy, and software designed exclusively for the medical community is limited. Software designed to allow manual preparation of image data into 3-D printable files can be labor-intensive, requiring hours of work. Using GE Healthcare’s advanced visualization tool, specifically designed for the medical community, VA radiologists will be able to produce models of normal and pathological anatomy using automation techniques that will speed up the pre-3-D printing preparation work and the diagnostic process. This is expected to reduce the time it takes to create 3-D models from hours to minutes.

Three-dimensional printing is primarily used to manufacture orthopedic implants and guide surgical cutting, and peer-reviewed research on potential impact in patient care has expanded exponentially. Recent industry and regulatory advancements such as the establishment of clinical guidelines, 3-D printing reimbursement tracking codes, and the integration of technology and software are all expected to support the widespread adoption of point-of-care 3-D printing in hospitals.

For more information: www.gehealthcare.com

January 22, 2026

January 22, 2026