May 20, 2014 — It is possible to use 3-D printer technology to create some types of customized medical devices on demand, and some research centers are developing technology to print more complex devices like heart valves using biocompatible materials. The Food and Drug Administration (FDA) has recognized the technology now exists to print these types of devices and is gathering information regarding technical assessments that should be considered when it will inevitably begin reviewing these types of future FDA submissions.

The FDA will host a workshop titled “Additive Manufacturing of Medical Devices: An Interactive Discussion on the Technical Considerations of 3-D Printing,” Oct. 8-9, 2014, from 8 a.m. to 5 p.m. in Silver Spring, Md. The purpose of this workshop is to provide a forum for FDA, medical device manufactures, additive manufacturing companies and academia to discuss technical challenges and solutions of 3-D printing.

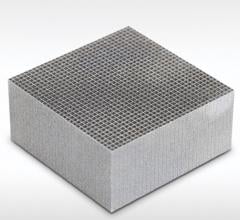

Additive manufacturing, also known as 3-D printing, is a fast- growing manufacturing technique that builds devices from computerized blueprints or models, by layering material only where it is needed as if building with interlocking bricks. Traditional methods of manufacturing remove material from larger pieces by cutting, drilling, and carving to create a final part. Through additive manufacturing designers can alter products quickly for rapid prototype iteration or produce small batches of multiple product designs in each batch. The 3- D computer models used to build each part can be created using traditional computer-aided design techniques or they can be made directly from 3-D image sources, such as computed tomography (CT) scans or magnetic resonance imaging (MRI). Designers can also use a combination of techniques. Consequently, the FDA said 3-D printers can create truly anatomically matched devices or surgical guides by utilizing a patient's own medical imaging.

Additive manufacturing is just beginning to enter mainstream use in medical devices. The FDA said this technology unlocks new avenues for creativity and innovation for medical device designers. For example, the FDA said it can facilitate the production of devices with intricate structures that were previously impractical or impossible. Current industry applications include using it as an alternative device production method for traditional components or as a primary method to create patient-matched devices. As the technology matures, additional capabilities may be incorporated into medical devices.

FDA said it already has begun to receive submissions using additive manufacturing for both traditional and patient-matched devices, and it sees many more on the horizon. Industry forecasts project significant growth of additive manufacturing in both traditional and innovative environments by 2025.

Additive manufacturing may or may not present new questions depending on its use. However, the FDA said it realizes there are technical challenges associated with the process from design to final product that need to be properly addressed in all cases to ensure patient safety and to promote innovation in a fast-moving field. Process verification and validation are especially important when devices are produced individually or in very small batches.

By discussing and addressing these technical challenges through an open forum, FDA would like to foster innovation with a transparent process and shared expectations for stakeholders. Participants in the October workshop will include researchers, scientists and engineers involved with the research and development of products using additive manufacturing as one or more steps of the manufacturing process. The intent is to address scientific and technical challenges posed by additive manufacturing process, but not address specific printing technologies or medical device types. The latter will still be covered by their respective standards and guidance documents. Ideas generated during this workshop may facilitate development of new draft guidance and/or standards for additive manufacturing of medical devices.

The FDA said it will include discussions on several topics, including preprinting considerations, including material chemistry, physical properties, recyclability, part reproducibility and process validation. Printing considerations will include printing process characterization, software used in the process, post-processing steps such as curing, and additional machining. Post-printing considerations will include cleaning/excess material removal, effect of complexity on sterilization and biocompatibility, final device mechanics, design envelope and verification.

May 01, 2023

May 01, 2023